Details

Function

The function of the U.S. Tray Deaerator is to remove dissolved oxygen, carbon dioxide and other noncondensible gases from boiler feedwater, thus preventing corrosion in piping, economizers, boilers and heat exchangers.

In addition, the deaerator heats the boiler feedwater and provides the deaerated water at saturated steam temperature to the boiler feed pumps.

Deaeration is achieved by:

- Heating the water to full saturation temperature at which point the solubility of any gas is zero.

- Cascading the heated water over trays to minimize the distance the liberated gas bubbles must travel to reach the surface.

- And, by the scrubbing action of the counterflow steam, sweeping the liberated gases from the surface of the water and carrying them out the vent.

Design and Operation

U.S. Deaerators are made with the vertical deaerator mounted on a horizontal storage tank or in all vertical configuration.

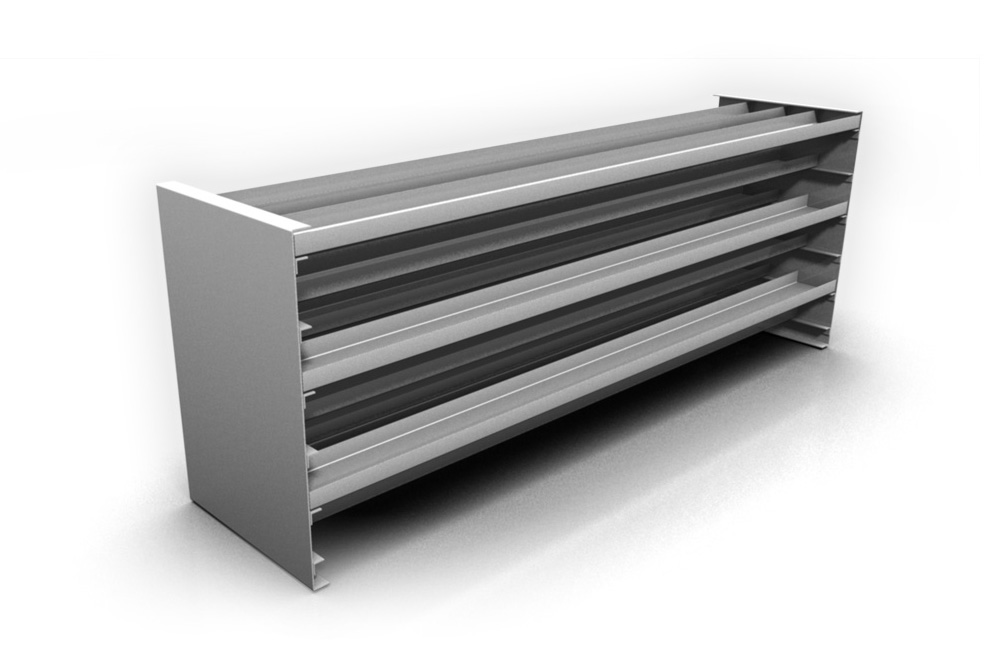

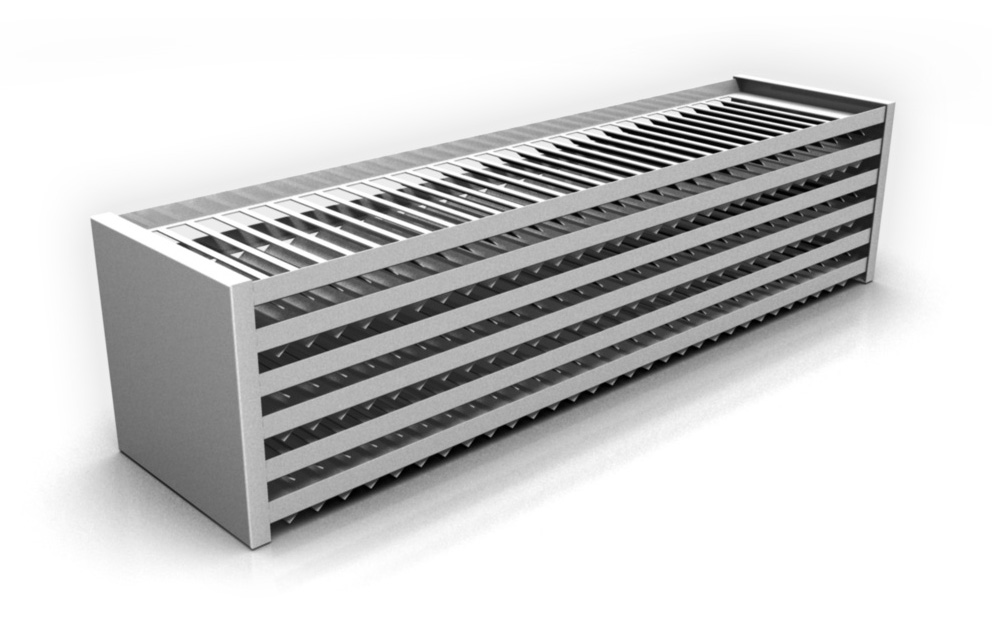

U.S. Deaerators utilize a three stage system to bring about complete deaeration. The water first enters the deaerator through a spray system that divides the water into tiny droplets in the presence of steam to heat the incoming water to near steam saturation temperatures. The water is then heated to full saturation temperature over the second stage heating trays and then cascades over the third stage air separation trays where deaeration to 0.005 CC/L (7 PPB) is performed.

Steam enters the bottom of the tray stack, rises counterflow through the air separating and heating trays, continues into the preheater/vent condenser and the noncondensible gases are vented to atmosphere.

The deaerated water is collected in the storage compartment and is now available to the boiler feed pumps.

Construction

The shells of U.S. Deaerator tray type deaerators are constructed of welded steel plate and internals are stainless steel. The deaerator shell and storage sections are furnished in compliance with ASME Code with Stamp and Certificate. The usual design pressure is 50 PSIG or higher. The entire tray compartment including the preheater/vent condenser is fabricated of stainless steel. All internal bolts are stainless steel and trays are usually made of 16 gauge stainless steel. Heating and air separating trays are easily accessible through ample manways in the pressure vessel shell and tray compartment.

Outstanding U.S. Deaerator Features

Simple spray pipe design – no moving parts – nothing to stick open or closed.

Heating and air separating trays are robust with more than adequate spilling edge and open passage.

Only clean incoming steam and deaerated water are in contact with pressure vessel shell.

Counterflow operation provides greatest possible deaerating action with the cleanest steam entering the bottom of the tray stack and sweeping contaminating non-condensible gases upward toward the vent condenser.